|

In this article Graham Baxter, G8OAD

and Steve Smith, G8LMX explain some fundamentals of quartz

crystal temperature turning points and describe how they fine

tuned their Z3801A oven oscillators. They adjusted the oven

operating temperature to closely match the inherent

temperature turning point of the quartz oscillator. Careful

measurements and patience can pay off in improved crystal

oscillator characteristics.

|

Graham was fortunate with his Z3801A. It was one of the

comparatively few units whose clock oscillator was well behaved, and

was eventually able to settle with a predicted uncertainty of around

300 ns.

However, Steve had one which seemed less

stable. The problem moved with the oscillator, so it was

determined that there was a fundamental difference between them. To

explore this without damaging his good oscillator, Graham bought a

second Z3801A which was known to be less stable. Steve had

dismantled his and examined it several times but had reached no firm

conclusions.

Since the problems seemed to be temperature related, we

wondered if the inner oven temperature was not correctly set to the

turning point of the system.

For an explanation we need to look at the graph of Figure 1

which is frequency versus temperature for an SC cut crystal. It is

in the form of a cubic with two points of inflection. The lower

temperature, or "lower turning point" is a frequency maximum. The

upper turning point is a frequency minimum. If the temperature can

be placed exactly on a turning point, then the temperature

coefficient of frequency will be zero. This means that for very

small perturbations of temperature, there will be no change in

frequency. This is an ideal that cannot be completely realized,

since the crystal is also sensitive to temperature gradients, and it

also exhibits some hysteresis. However, these effects are minimized

in the case of the SC cut crystal compared to the AT

cut.

Figure

1

The upper turning point is most commonly used for an AT cut

crystal, where it can be typically arranged to occur at 65 - 85

degrees. However, the upper turning point for an SC cut crystal

often is too hot for reliable use in an oven, so the lower turning

point is usually chosen. To find the correct temperature, one simply

has to adjust it for a frequency maximum. It sounds easy, but keep

in mind that we are aiming for a precision of a few

milli-degrees.

|

Z3801A inner oven

temperature bridge

|

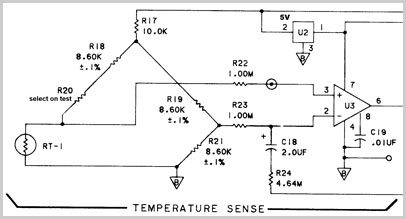

The temperature controller of the 10811 has a bridge, which

comprises three precision resistors and a thermistor that changes

resistance according to temperature. The thermistor is embedded

within the inner oven, but the component wire leads are accessible.

There is a 'select on test' resistor, whose value is chosen in

accordance with the temperature that is marked on the crystal.

However, this assumes that the crystal was correctly marked when

new, that the turning temperature has not changed, and that the

turning temperature of the assembled oscillator is identical to that

of the crystal alone. We decided to ignore the markings on the

crystals and start from scratch.

Figure 2

Figure 2

Z3801A

inner oven temperature bridge

The first step must be to accurately measure the bridge

resistors. If any resistors have drifted from their marked values

they must be replaced, otherwise they will continue to drift.

Fortunately, our resistors seemed beyond reproach.

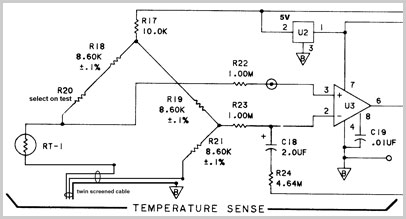

Our procedure was to bring test leads to the outside of the

double oven so that the bridge temperature could be varied at will.

This had to be done with some care. We decided to use a length of

the very lightweight twin screened cable of the kind used for tape

head connections.

The 'lower' end of the thermistor, and the lower resistor on

the opposing side of the bridge were disconnected and carefully

connected to the two inner wires of the screened cable. The braid

was connected to the original common point of the thermistor and the

resistor as shown in Figure 3.

A

note was made regarding which color conductor was connected to the

thermistor. A small hole was drilled in the oven casing and the lead

was passed through. The inner oven was then reassembled.

The

reasons for doing this were:

|

We

did not know in advance which way the temperature needed to be

moved.

By

introducing identical wiring into both halves of the bridge,

the effects of the cable resistance, temperature coefficient,

and any thermal e.m.f. would tend to cancel.

The

braid would be connected to the negative supply, which is at

RF ground. |

A

note was made regarding which color conductor was connected to the

thermistor. A small hole was drilled in the oven casing and the lead

was passed through. The inner oven was then reassembled.

Figure 3

Z3801A oven temperature bridge with external

wiring

During manufacture the connecting leads to the inner oven are

passed twice around the inner oven. They are then routed through the

outer oven and twice around that as well. This was done to minimize

the effect of thermal shocks traveling down the copper. We

considered it was important to replicate this technique with the

routing of the screened lead, so it was dressed to follow a similar

path.

The outer oven was reassembled so we now had clock assemblies

with just an extra twin screened wire. If the two inner wires are

connected to the braid, the system will work as before. For the next

stage you need a resistor substitution box, or a precision low-value

multi-turn pot and a selection of high stability resistors.

Arbitrarily choose an inner core and connect it to the resistor

substitution system. Connect the braid and the unused inner wire to

the other end of the resistor system. Start with the resistor set to

zero and allow the system to stabilize for a few days.

The task of finding the turning point is made much easier if

you have a second frequency standard with good short-term stability.

It is possible without one, but it is a very tedious task.

The procedure we followed was:

Put

the Z3801A into holdover and let it recover from the initial

disturbance for about 20 minutes.

Compare the frequency of the Z3801A with that of

your secondary standard. One way is to externally trigger your

oscilloscope from the standard oscillator and watch the Z3801A

signal drift. We used a phase meter and a data logging system

to plot graphs.

Introduce some resistance of about 100 ohms. You

might see a small transient disturbance, but wait two minutes

and note the effect on the frequency. If the frequency has

fallen, add a further increment to make absolutely sure. If it

continues to fall, then you are moving away from the turning

point. This means that you chose to start with the wrong wire!

Correct it and allow it to stabilize again.

Continue moving the temperature until the

frequency reaches a maximum and starts to

fall. |

Make plenty of notes, since one change every ten minutes is

adequate and you may get distracted from your adjustment procedure.

When you have a rough idea of the amount of resistance to be added,

fit a high quality fixed resistor of a value a little less than the

needed value, and then explore again in smaller increments. The

reason for fitting the fixed resistor in series with the variable

one is to avoid having the temperature coefficient of the resistor

box involved in the measurements.

We

found that Graham's Z3801A needed to go cooler by the equivalent of an extra 1750 ohms

in the resistive side of the bridge. On the other hand, Steve's

oscillator needed to go hotter by 1880

ohms in series with the thermistor. In both cases they were in error

by several degrees. It is well worth spending a few weeks tuning the

temperature, ultimately in one-ohm steps. The Z3801A can still be in

normal use apart from the short spells of holdover.

Explore in both directions. Hopefully you will find a value

where an ohm either way makes no difference. In the absence of a

second standard it is just about possible to perform the adjustments

while observing the TI during holdover. However, there is limited

resolution available, and the GPS signal is not really stable enough

in the short term.

Once you are absolutely convinced that you have found a

frequency maximum, you will need to dismantle the oscillator once

more and carefully fit a fixed resistor of the exact measured value

into the appropriate position at the lower end of the bridge. There

is no need to allow for the resistance of the cable since it

affected both sides of the bridge equally. Seal the hole with solder

and reassemble. The performance should further improve once the

selected resistor is in the oven.

|

(a) Be wary of making too large a change of temperature

in one step. The Z3801A monitors the oven health signal, and

if it sees the heater turn full on it flags this as an error

and resets.

(b) Keep your cell phone away from the

resistor substitution wiring.

(c) We paid a lot of

attention to C18. We measured the leakage current vs

temperature for a selection of brand new film capacitors. We

never found one to outperform the original C18.

|

|

OK, I need an 1880 ohm resistor.

Now what?

Rather than try to use a high tolerance precision

resistor of .1 per cent or better, you are likely to achieve

results closer to your target value by simply selecting a

resistor from a low tolerance batch. Assuming you have a

reasonable digital ohmmeter, finding your specific resistor

should not be too difficult.

Searching from a group of five per cent resistors is

probably easier than limiting your search to a batch of one

per cent resistors because the 5 per cent batch will have a

tendency to have distributed values. Also, if you need to add

a total of 1880 ohms to the circuit, using a resistor within

plus or minus ten ohms is going to make a very big improvement

to the circuit.

A little patience sorting through some low cost high

stability (carbon or metal film) resistors should yield a

value nearly at your target, and at a cost much less than

using a high tolerance precision value

resistor.

Steve Smith reported that he and Graham were able to

find their exact values amongst their 5% high stability

resistors at a cost of only a few pennies each. With care, there is

room to allow the use of two

resistors. |

|

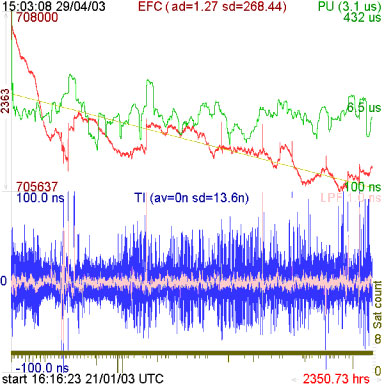

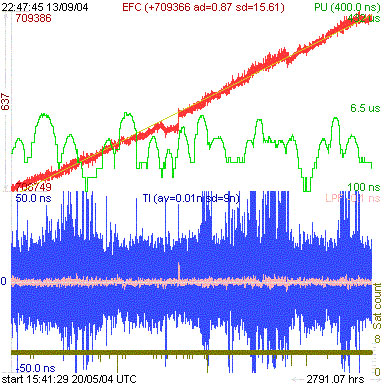

Before and after GPSCon

performance charts illustrate the benefits of fine tuning the

oven temperature to closely match the turning point of the

quartz oscillator. Obvious improvements in EFC stability (red

trace) and lower overall predicted uncertainty values (green

trace) are shown. On both charts the TI (blue trace) is the

same scale. The reduction in 'noise' is significant when both

charts are compared.

The apparent high aging rate of the "after" plot is due

to the receiver being inactive for over four weeks because of

an unrelated fault and not as a consequence of the temperature

tweak. This is why the early aging rate is so steep in the

"after" plot. |

Oscillator performance before

adjustment

Oscillator performance after

adjustment

|

How the measurements were

made |

|

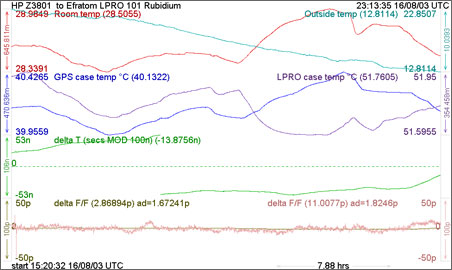

The phase measurement of the rubidium to GPS is done

with a HP 3575A phase meter with its recorder output connected

to a Solartron 7150 GP-IB multimeter. This in turn is logged

by Graham's customized Viewer program which he has modified to

read from an IEEE-488 card in the PC. This gives a resolution

of less than 10 pico seconds.

The temperature plots are done with Steve's custom

designed serial interface PIC board, also logged by Graham's

Viewer program, with 10 bits of resolution. Some of the

equipment below is home constructed. Notice Steve's use of a

recycled HP equipment cabinet (bottom in the photograph) for

his rubidium oscillator. |

|

The logger is plotting the air temperature of the part

of the room where the frequency standards are located. It is

also plotting the output of a phase meter which is scaled to

display nanoseconds of time difference between the 10 MHz

outputs. The time trace is also differentiated, filtered and

scaled to produce an instantaneous fractional frequency error.

|

Copyright © 2003-2006 by Graham Baxter, G8OAD

and Steve Smith, G8LMX